General description #

Qbil-Trade provides a module for business units that have their own factories and manufacture their own items. This module allows you to manage the orders that arrive (incoming) and depart (outgoing) from these factories. All orders that have not been finished (finalised) are displayed on the own factory screen. You can change order data such as arrival and departure dates, weight, product analysis, and so on. These details are kept up-to-date by the workers in these factories. It’s also worth noting that people who can see this screen don’t normally have access to the order screen. So they may adjust the order’s status, such as whether it’s been finalised or not, from this panel, which is also updated on the order screen.

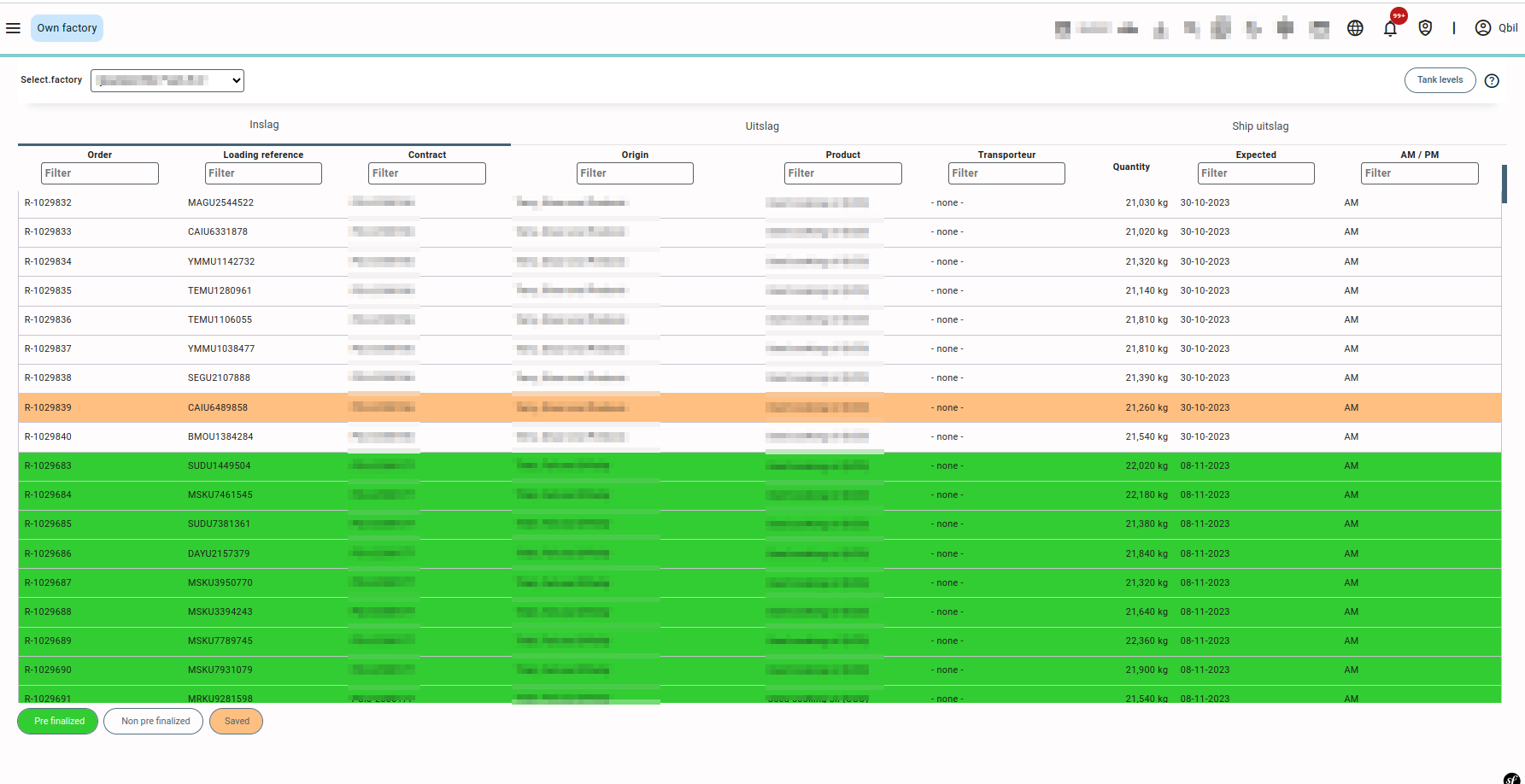

Overview Screen #

The overview screen displays the listed own factory orders. These orders are displayed on the basis of the factory selected in the “select factory” drop-down. The various orders (incoming, outgoing and ship outgoing) are displayed on the screen. These orders are displayed in three separate tabs: inslag for all incoming orders, uitslag – for all outgoing orders and ship uitslag – for all outgoing orders for which the mode of transport is ship.

Colour scheme:

The orders on the own factory screen are displayed in various colours as per the given schema.

- Pre-finalized: All the pre-finalized orders are shown in green. Pre-finalized orders are the orders that have been marked/checked as finished using the checkbox “order finished” on the own factory order screen. These orders once finalised on the order screen, disappear from the own factory overview screen.

- Non-pre-finalized: All the non-pre-finalized orders that are not saved yet in the own factory screen are shown in white. To save an order, you need to enter the mandatory details which are, the factory user and weighing ticket number.

- Saved: Saved orders are shown in orange. The orders which are saved but not pre-finalized that is, marked as “order finished” are displayed in orange colour.

Own factory screen displays orders in three tabs:

Inslag #

Inslag displays the orders/order lines for incoming orders into the factory(silo). These orders define the details of the order that are arriving in the factories. You can also print, preview or email the warehouse receipt using the buttons on the top of the screen.

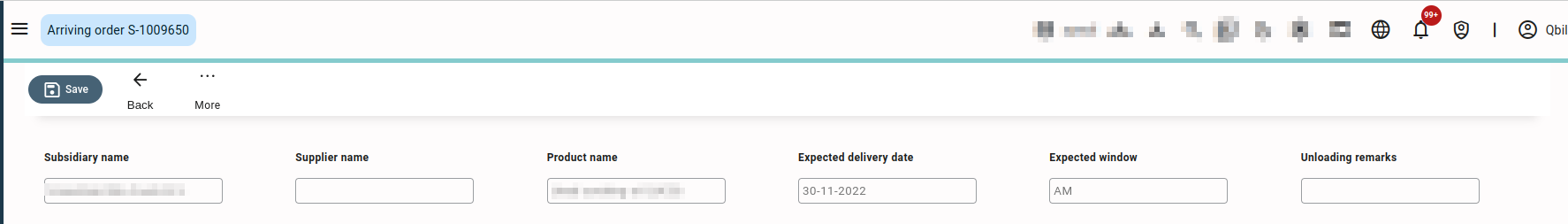

Details: This section displays the basic information of the order like subsidiary name, supplier name, product name, and expected delivery date.

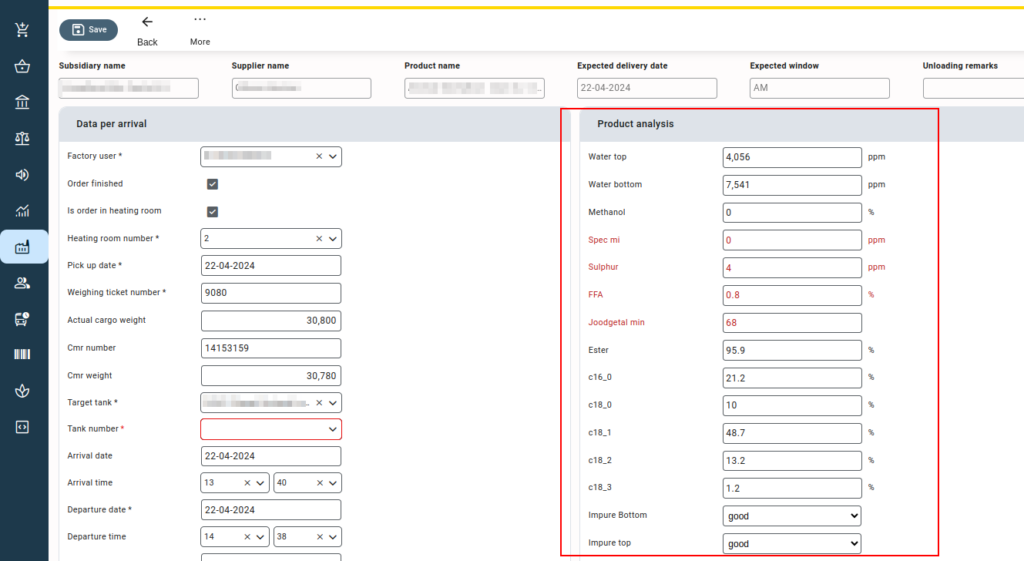

Data per arrival: The details in this section are entered by the factory workers on arrival and departure of goods. The details added in this section include arrival and departure time/date, CMR number, weighing ticket number, and other cargo data.

You can also enter the details related to the heating rooms like number, pick up date, etc in case the goods are placed in the heating rooms before unloading them in tanks. This also allows you to keep track of the time the goods were stored in the heating room.

Product analysis: The factory users in this section enter the product analysis details of the purchased product, which are checked on a sample of the product in the laboratory. Each field will have a set of properties, some of which might vary a bit per user (labels, limits, etc.). The product analysis fields may vary according to the configuration.

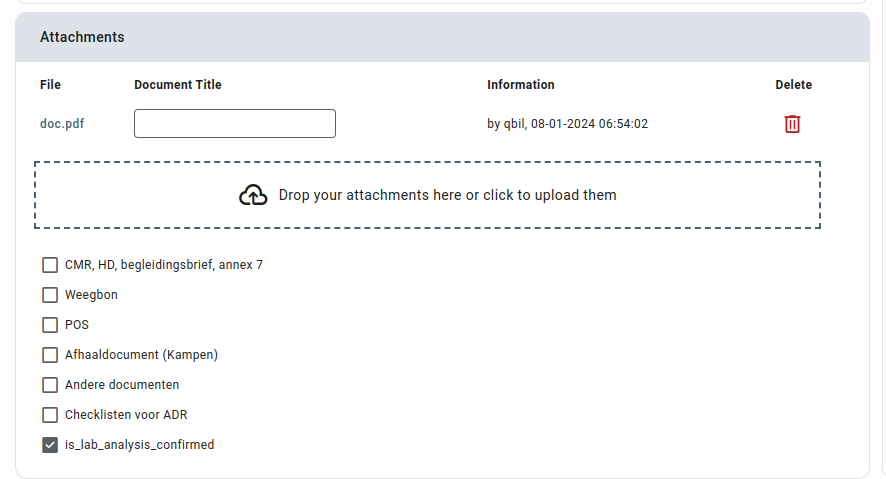

Attachments: The attachments section allows you to attach documents and check the corresponding checkbox. Later when you print or email the Warehouse receipt or “magazijnbon”, it also displays the name of the attached documents.

Uitslag #

Uitslag views the orders/order lines for outgoing orders from the factory/silo. The various details related to these orders are displayed and the factory workers can also update these details. You can also print or email various documents related to these orders like handelsdocument, magazijnbon, etc.

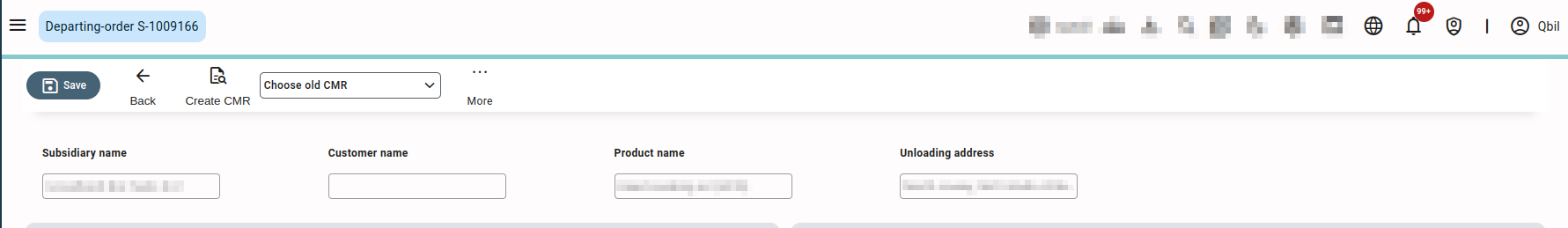

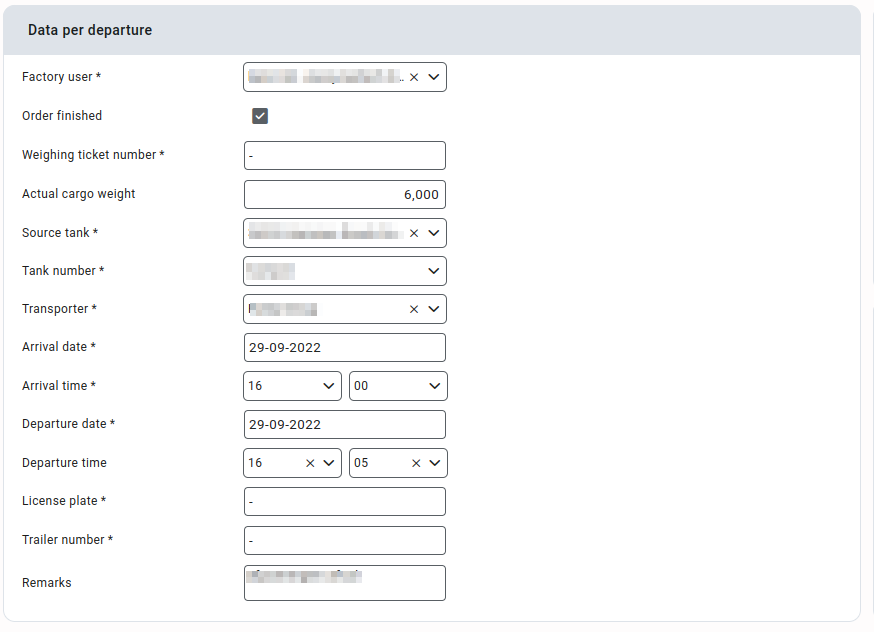

Details: This section defines the basic information like subsidiary name, customer name, product name and unloading address. You can also create CMR for the order in this section.

Data per departure: This section displays the various details related to the arrival and departure of goods from the factory like date, time, weight, etc. the details in this are updated usually by the factory workers who received or departed the goods from the silo the other details updated in this section are weighing ticket number, actual cargo weight, tank number, source tank, etc.

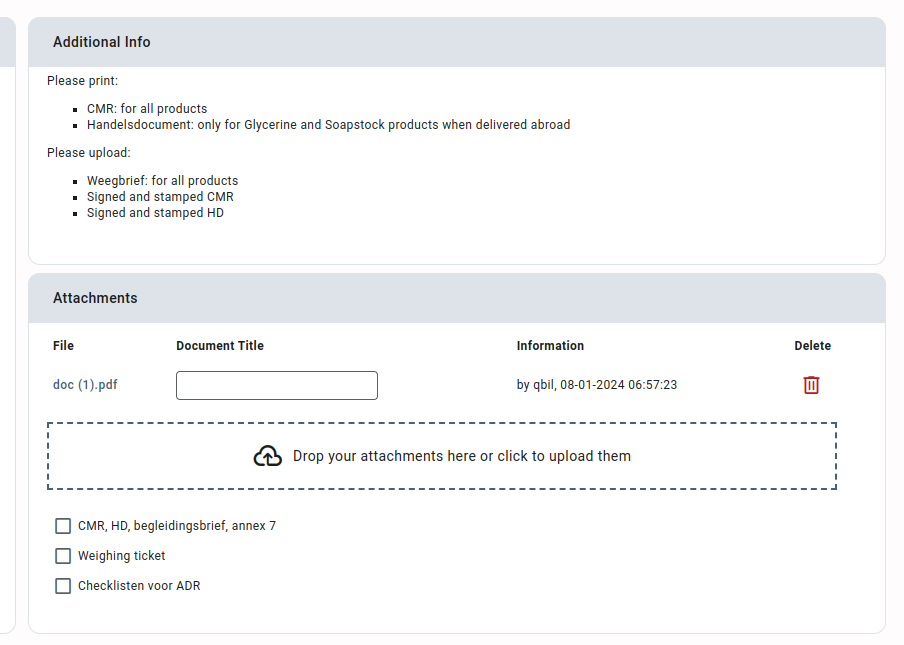

Attachments: The attachments section allows you to attach documents and check the corresponding checkbox. Later when you print or email the Warehouse receipt or “magazijnbon”, it also displays the name of the attached documents.

The section also mentions the documents to be attached and printed with the order.

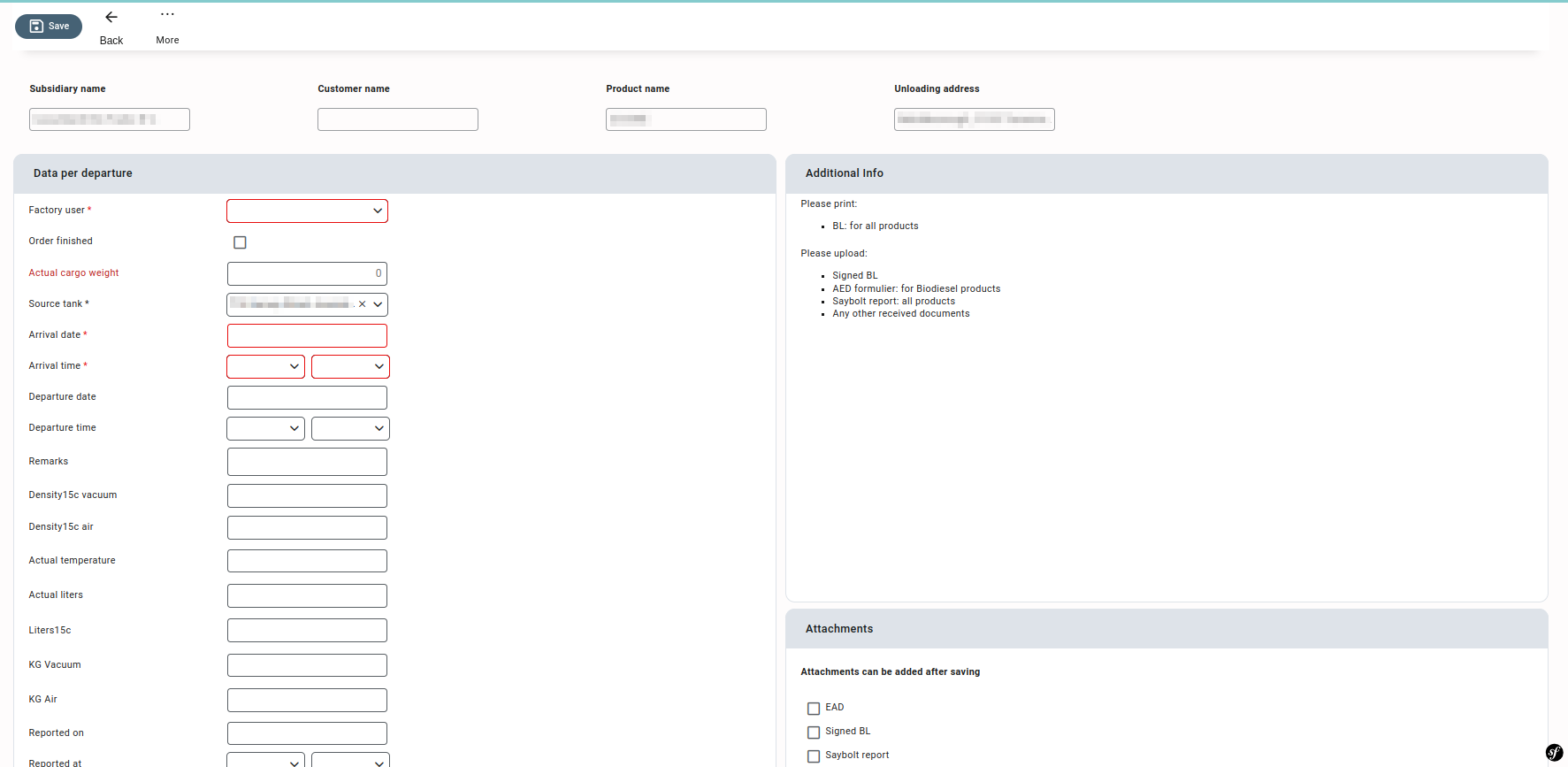

Ship Uitslag #

Ship uitslag displays outgoing orders that are being transported by ship. The details in the orders are similar to that of uitslag orders except for a few details which are specific to transportation by ship. These details are updated by the factory workers when departing the order from the factory.

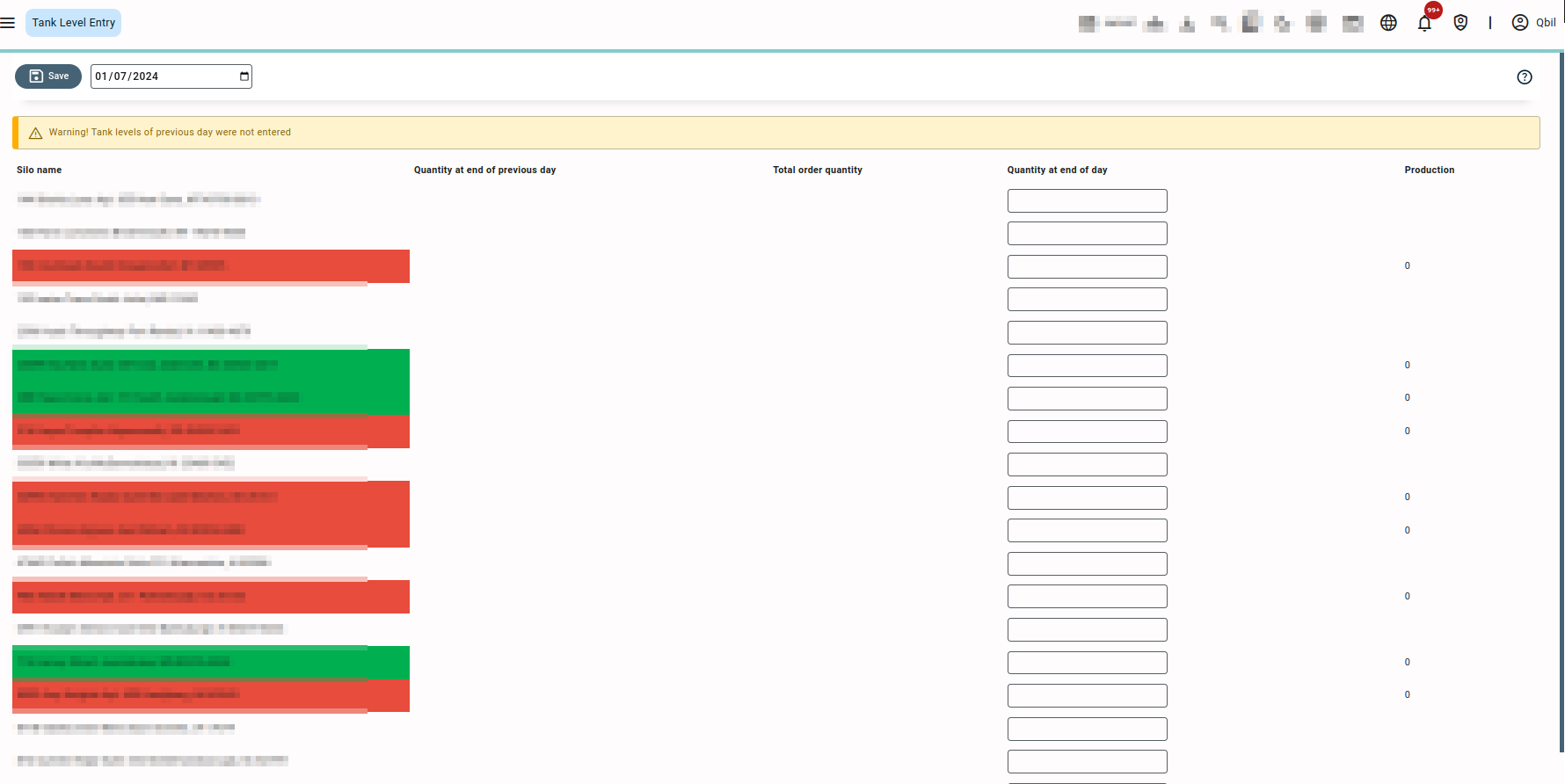

Tank Levels #

Tank levels navigate the user to the other screen, where the quantity of the product in various tanks(silos) is displayed. The tank level screen allows you to select the date, enter the total quantity of product in the tank on that day and save it. The selected date will be used to display the data like quantity at the end of the previous day and the total order quantity.

The red colour indicates incoming orders in the tank and outgoing orders are shown in green.

Note: The value of the ‘total order quantity” is calculated as: (Quantity moved into a silo – Quantity taken out from silo) on that day. The value shown in the production field is calculated based on the product’s availability in the tanks as (Quantity at the end of day – Quantity on the previous day – Total order quantity).