General description #

A production order is a trading operation in which purchased products are processed, mixed, or/and converted into a new product called a resultant or manufactured product. The resultant product is stored in a lot of the company warehouses. At some point, a production order will be coupled to an order. That order decides what happens with the resulting product (to stock, sales contract, or direct sale).

Creating a new product via production order #

- Press or click the “+” button.

- Enter the details related to the order. Make sure to fill in all the mandatory fields marked in red.

- Enter the details in the production order date and expected cost sections.

- Press or click “Add” on the ingredient side.

- The quantity on the result side is automatically calculated per the ingredients’ quantity but can also be edited per requirement.

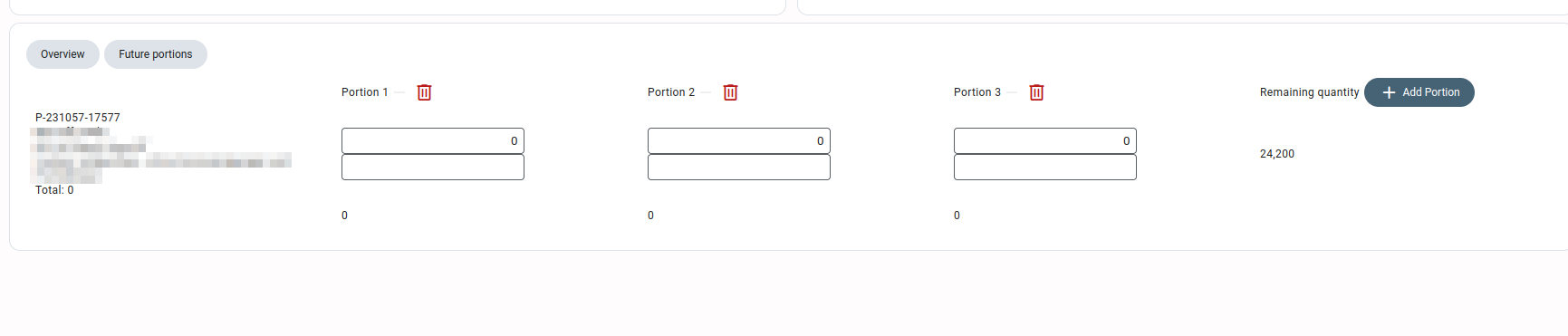

Production order portions #

Before saving the order, there is an additional feature ‘to split’ a production order into portions. The quantity you have added from each ingredient forms one portion of the total production order. This separation into portions gives the possibility to split a production order over multiple orders (multiple deliveries). The production order cannot be saved when no ingredients are selected.

The input of ingredients is used to produce the selected, resulting product. A lot will be selected from the source side with a specified quantity. Only those lots associated with the selected warehouse will be displayed.

Optional reserving: An optional step is immediately matching orders to this production order. This order would function as reserving the resulting product of the production order.

Saving and finalizing the order #

- On saving the order, if there is any difference, it will display the pop-up before ‘There is a difference in nett weight between source and result, proceed with storage?’. You can evaluate the difference or proceed with it and save it.

- The warehouse field is disabled after saving the production order.

- Before finalizing, the ‘Not all sources are final’ message is shown. That means, all source side lots used in any orderline should be finalized first, and then you can finalize the production order.

Actions #

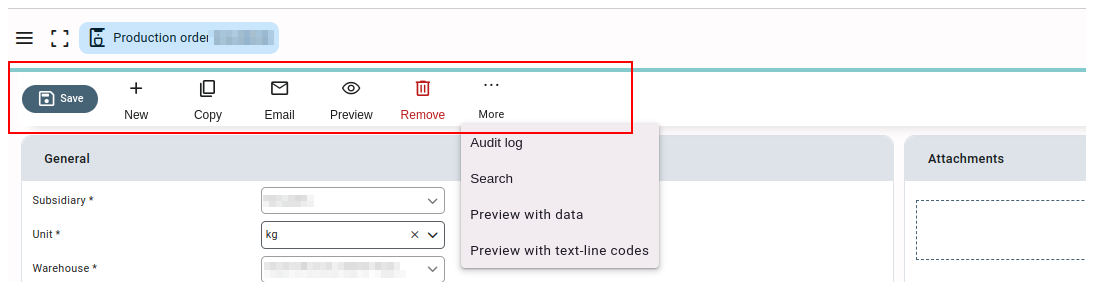

After saving a production order, you can perform various actions from the order using the action buttons on the top section of the order. The various actions that can be performed are:

- Save: You can save any changes made to the production order using this button.

- New: You can create a new production order using this button.

- Copy production order: You can create a new duplicate production order using this button. The duplicate production order copies all the details from the general, expected costs, and production costs sections of the original production order. The ingredient details are not copied while copying a production order. If any attachments are added to the original production order, a pop-up window appears asking if you want to copy the attachments, and you can choose whether or not to copy the attachments.

- Email: You can send the production order to your relations using this button. The button opens a pop-up in which you can change the details like the sender, receiver, cc, or bcc for the mail. You can also attach the files to the mail and change the mail body, etc. on the pop-up.

- Preview: You can preview the production order layout using this button.

- Remove: Using this button, you can delete the production order. The production order can only be deleted if the resultant product is not used in any order.

- Audit log: The summarised details about the log of the production order are displayed in a pop-up box using this button. The pop-up usually shows the name and time details of the user who created the contract or made changes to the contract.

- Search: This button redirects you to the production order overview screen, where you can search for any production order.

Detailed explanation of certain fields #

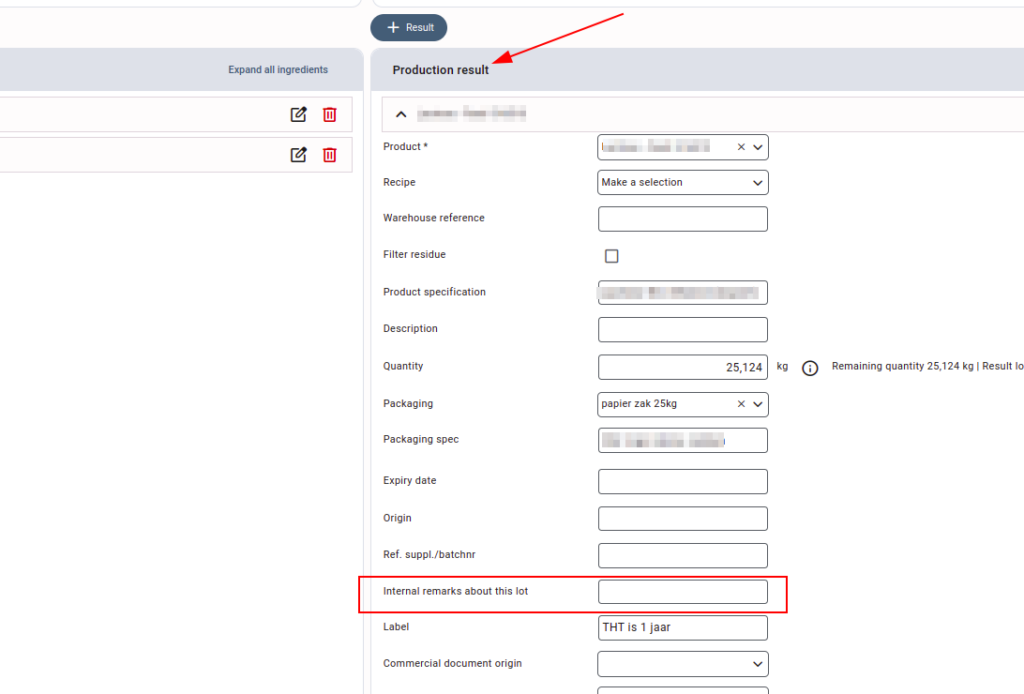

- Internal remarks about this lot: This field on the production result section can be used to add any comments or notes about the lot where the product from the production order is stored. These remarks will also be shown on the lot screen, ensuring that any important details about the product are visible in the associated lot.